| 1/7 | 002 Return to MSR&LHA Home page |

|

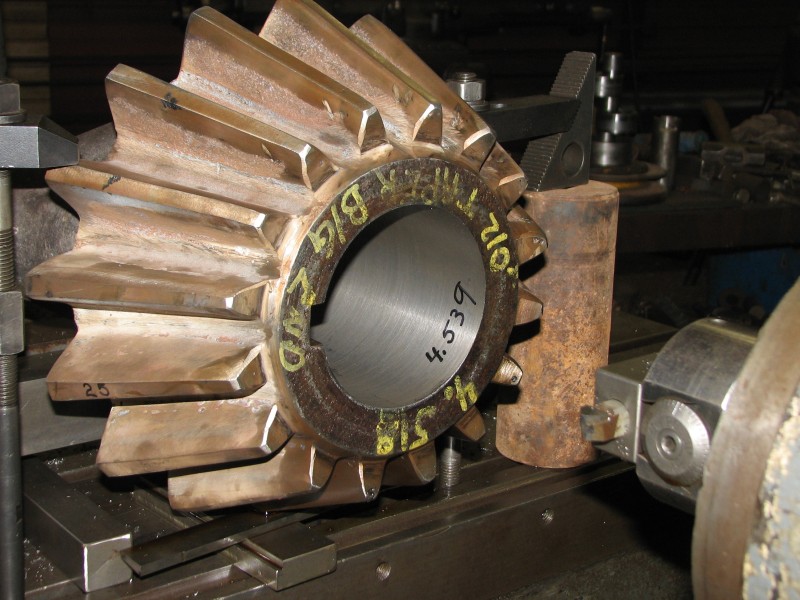

This photo shows finished bore, about .031 inch bigger than the close end of the

bore was originally. From the writing on the hub end, the close end was .012

inch bigger than the far end, but this leaves out the part that the middle

portion was smaller than either end. In other words, the bore was shaped very

much like the contour of power-plant cooling towers. While re=boring the gear, I

tried to use HS tool steel, but found that inclusions cast into the gear trashed

the tip of the cutter, about half way through the hole, causing the bore to

taper. If the original machinist simply reversed the feed of his machine and

back-bored, without sharpening his cutter, may explain the small-in-the-middle

condition that was found in this gear. After attempting to spot-grind out the

hard chunks and stay with the tool steel cutter (which did not work) the shown

carbide cutter was installed, as per Christy's suggestion, and the boring was

completed with less than .001 taper.

Photo by Rick Brigger |